Manchester’s recycling and waste management in good hands

From left: Brent Jones, Pat Vailliencourt, Marsha Chartrand, Michael Sessions, Larry Jones of LRS. Each bale of plastic weighs about 10 tons.

by Marsha Chartrand

Every week, those of us who live in the Village of Manchester, and many who live in Manchester Township, see the familiar “Modern Waste” trucks (now evolving toward trucks with the LRS logo) coming through to pick up our trash and recycling.

But where does all of that trash go?

Village President Pat Vailliencourt, Village Manager Michael Sessions, Village DPW Supervisor Brent Jones, and myself went on a tour of LRS’ refuse transfer station in Napoleon on June 20, hosted by Larry Jones, LRS General Manager, to learn the answer to that question and more. Following our visit there, the Recycle Ann Arbor facility on Platt Road was our next destination, where we saw their philosophy of recycling in action.

At LRS, with the recent transition from Modern Waste, there has also been some staff transition, but a large percentage of the staff has stayed on to serve the community. LRS is known as an industry leader, providing innovative and environmentally responsible waste and recycling solutions for the communities they serve — including Manchester. With approximately 74 employees onsite at the Brooklyn Road site in Napoleon, the company has a renewed focus on safety, accountability, and community-building.

“We have worked hard to get this facility cleaned up,” Jones said. And, indeed, the yard is clear and all solid waste is sheltered inside the buildings until it is picked up and trucked to the next transfer site. As far as safety, Jones noted that the company has invested $65,000 in new lighting so far, with more to come. And the new front-loading trucks are an added safety and cost-savings factor, allowing the drivers to remain safely in their vehicles and complete each pickup in 30–45 seconds rather than the two minutes-plus it would take with the older trucks. The larger trucks are also far more efficient in that they will handle pickups from 1,1,00–1,200 residences, while the rear-loading trucks would only take trash from about 250 homes per trip.

One pickup per day in Manchester can handle the trash, while the second sweep through town will get all of the recycling. That is why there is normally a lag of a few hours between the time your trash and your recycling are collected.

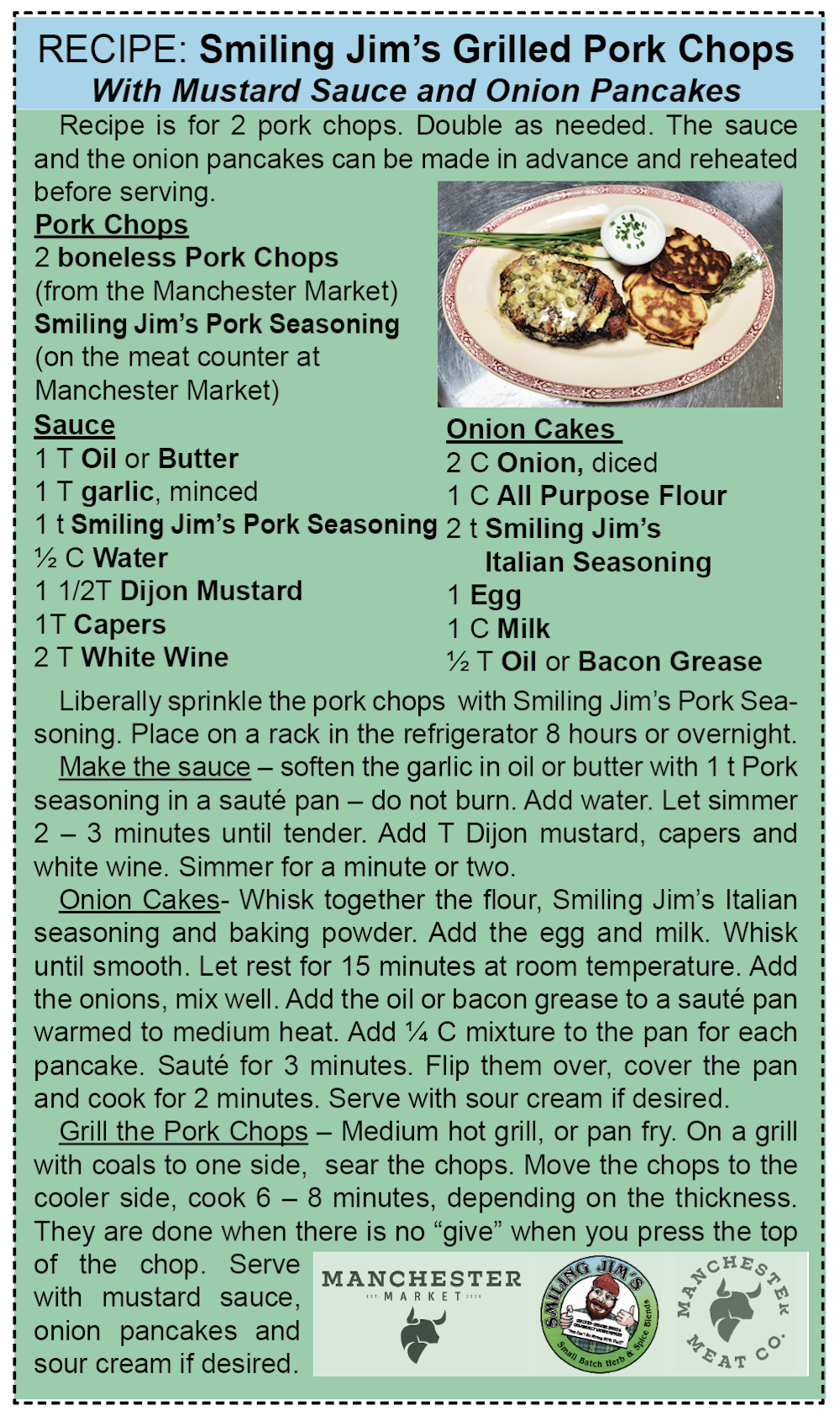

Trucks return to the transfer facility and the trash and recycling are sorted separately. Recycling is then transferred to the state-of-the-art Recycle Ann Arbor facility, where it is hand-sorted through the process — some by humans and some by robots. Robotic sorters are a huge investment for Recycle Ann Arbor, as it is a leap into the future and also a steep learning curve for the robots and the human staff.

“We have a different philosophy here,” said Bryan Ukena, CEO of Recycle Ann Arbor. Recycle Ann Arbor’s stated mission is to develop and operate innovative reuse, recycling, and zero-waste programs that improve the environmental quality of the community. A non-profit 501(c)(3) organization, Recycle Ann Arbor is an operating industrial site handling 22 tons of recyclable materials per hour.

“Our secret sauce is our people,” Ukena says. “We are a union shop. We have a different business model, and our pay scale is the best in the industry. These folks have bragging rights!”

One reason that Recycle Ann Arbor can remain so competitive is that they work hard to keep their product local. Their plastics go to Dundee, where milk jugs and detergent bottles are made directly into new plastic bottles. A tree-free paper mill in Wapakoneta, Ohio, is the destination for most of the cardboard and paper products recycled by Recycle Ann Arbor. They cooperate with other local recycling businesses, to keep costs down and retain environmentally sound practices.

“We do our due diligence,” says Curt Curavo, General Manager, who shares Ukena’s passion and enthusiasm for what they do at Recycle Ann Arbor. “This is the most comprehensive recycling facility. … In many ways, it’s more like a laboratory than a processing facility.”

Curavo explains that the staff takes pride in being able to quickly sort and remove things that are not recyclable, to keep things flowing smoothly on the lines.

“The #1 contaminant in a recycling plant is a lithium-ion battery,” he notes. “And #2, is plastic bags. Don’t put your recycled items in a plastic bag. Just throw it in the container loose.”

Lithium-ion batteries are dangerous in the facility as they can cause a fire that would shut down the plant immediately — sometimes for days. Obviously that’s a huge loss of time and money for a non-profit business. Those items are accepted, however, at the Drop-Off Station, 2950 E Ellsworth Rd, and Washtenaw County’s Home Toxics disposal site (705 N Zeeb Rd).

A Materials Recovery Facility — whether a transfer facility or a recycling facility — can be a hazardous workplace, Curavo says. “It can actually be more dangerous than a First Responder position,” he states.

Dedicated management, dedicated staff. All they need is dedicated recyclers to complete the circle. To learn more about what is accepted in your recycling bin, check out this listing from Recycle Ann Arbor: https://www.recycleannarbor.org/a-z-recycling-guide

Sorted, recycled plastic on its way to be baled.

Trucks enter this floor at Recycle Ann Arbor and dump their loads. They are then sorted to different conveyors.

The familiar Modern Waste trucks will soon be replaced with the LRS logo.

Brent Jones and Michael Sessions look at “SamurAI,” the robotic sorter, while Curt Curavo of Recycle Ann Arbor describes how it works.

You must be logged in to post a comment Login